When you’re tasked with ensuring precise tension measurements in cables or ropes, understanding the nuances of tensiometer calibration is crucial. You know that the right calibration equipment can make all the difference, but have you considered the impact of GAC versus SSAC calibration methods? Each approach has unique advantages and challenges that could affect your results and equipment longevity. As you explore these topics further, you’ll discover key practices that can enhance safety and performance in your work. What might you be overlooking that could elevate your calibration process?

Understanding Cable Tensiometers

Cable tensiometers, known for their ability to measure tension within cables, wires, and ropes, play a crucial role in various engineering and construction applications. As a calibration technician, you understand that ensuring calibration accuracy is vital to prevent measurement errors that could lead to safety issues.

The calibration process involves precise adjustments to align your force-measuring instrument with established calibration standards. You’ll encounter calibration challenges when working with cable tensiometers, especially when using different cable types.

Load cell calibration must be performed meticulously, considering the specific characteristics of each cable to maintain measurement integrity. Aligning calibration practices ensures that your equipment consistently meets the required specifications.

Regular calibration enhances the reliability and extends the lifespan of your cable tensiometers. Adhering to industry standards and manufacturer recommendations can significantly reduce the risk of discrepancies in tension readings.

This diligence ultimately contributes to the overall safety and performance of your projects. Remember, a well-calibrated tensiometer is essential for accurate tension measurements, so invest the time and effort needed for effective calibration processes.

Essential Tensiometer Calibration Equipment

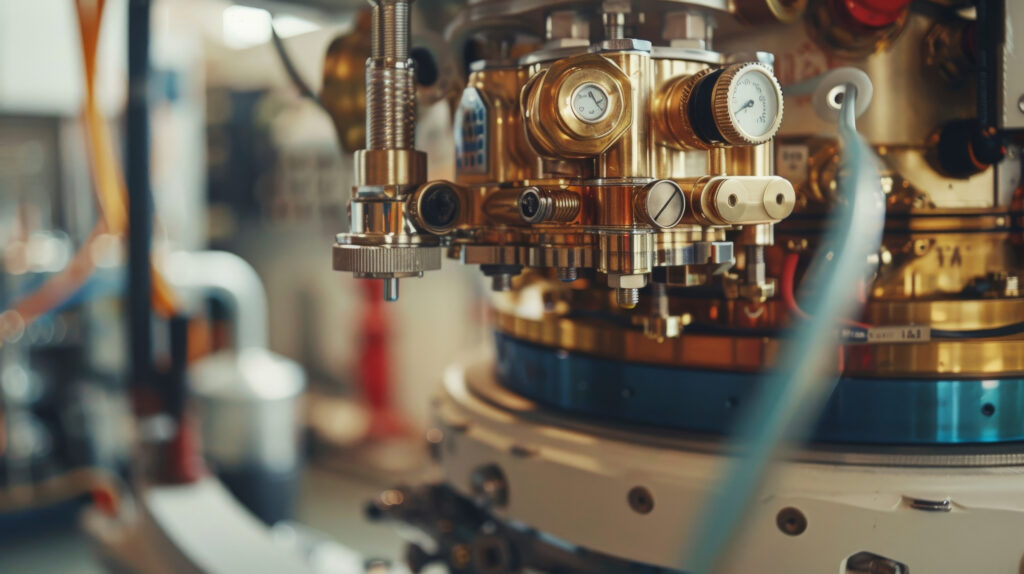

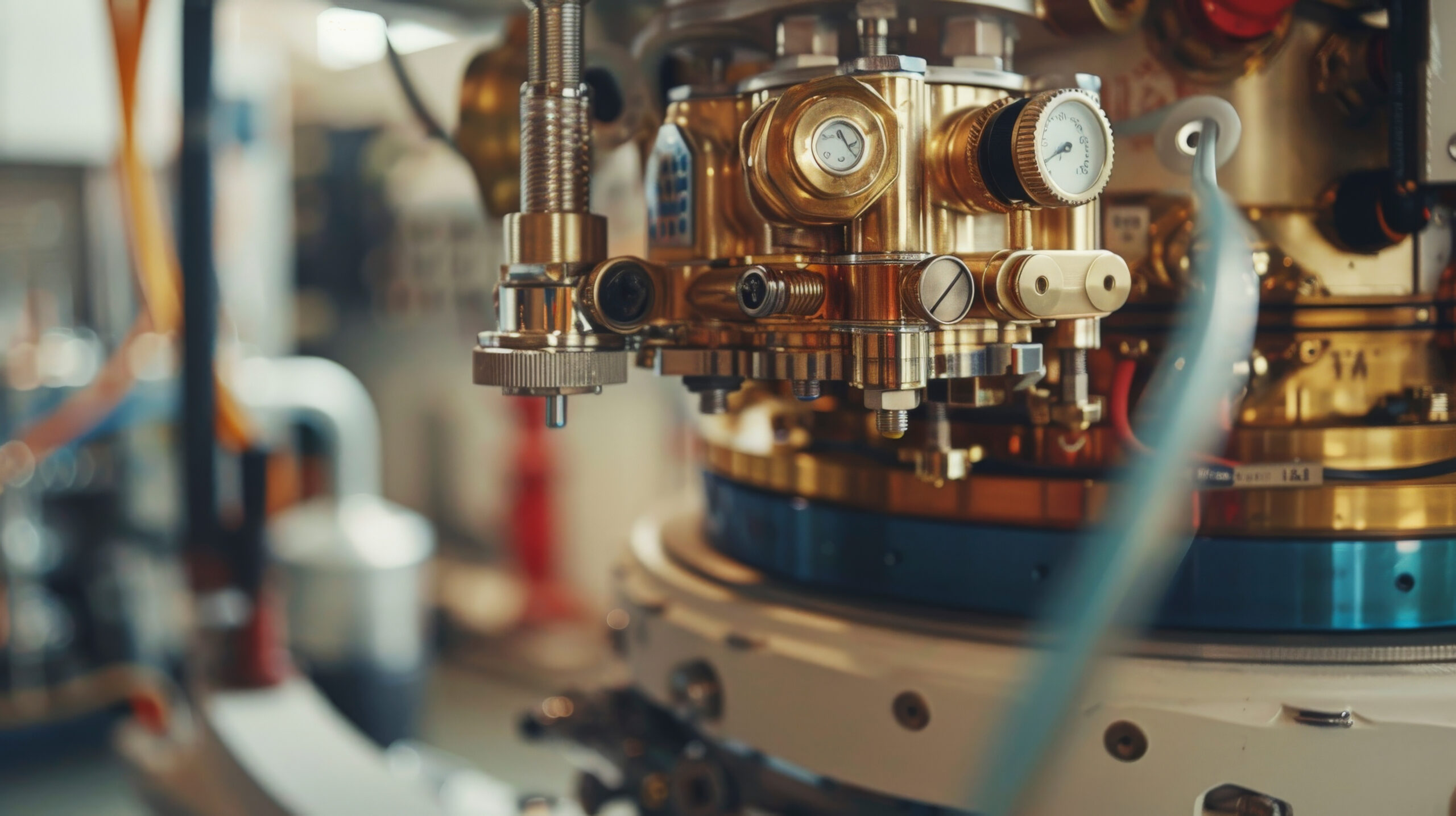

The right calibration equipment is crucial for ensuring accurate tension measurements in cable tensiometers. To facilitate various calibration processes in your calibration laboratory, you’ll need essential tools like calibration adapters and load cells.

For instance, load cell shunt calibration is vital for verifying the performance of your measuring devices, while button load cell calibration ensures precision in compact applications.

You should also be prepared for compression calibrations, which play a significant role in testing cable tension. The appropriate calibration equipment can help you meet the stringent calibration requirements necessary for reliable measurements.

Remember, a calibration certificate is essential to confirm that your equipment meets industry standards and functions correctly.

It’s essential to understand how each may affect your calibration results when dealing with different cable types, such as GAC vs. SSAC cables. Ensuring that your calibration equipment is well-maintained and suitable for the specific applications you’re working on will contribute to the accuracy and reliability of your tension measurements.

Prioritizing these elements will help you calibrate your cable tensiometers effectively.

Differences Between GAC and SSAC

Understanding the differences between GAC and SSAC cables can significantly impact your results when calibrating tension measurement devices. GAC (Galvanized Aircraft Cable) generally shows a different calibration response than SSAC (Stainless Steel Aircraft Cable).

When looking at your calibration chart, note that the standard deviation for GAC is often around 1 lb or better, while SSAC may yield 1 to 3 lb variations in repeated measurements.

You should also consider thread engagement when using these cables. Different adapters for compression calibrations may be required depending on the cable type you’re working with.

Additionally, refer to your calibration card and make sure your calibration equation aligns with the specifications for each cable type.

When using high-res PDFs for reference, ensure that your testing protocols align with the unique properties of GAC and SSAC. Understanding these distinctions will enhance your calibration accuracy and minimize measurement risks.

Always double-check your setup and ensure that your equipment adheres to the necessary standards for either cable type. This attention to detail will help you achieve reliable and repeatable results in your tension measurements.

Overview of Calibration Services

Calibration services play a crucial role in ensuring the accuracy and reliability of measurement devices across various applications. Proper calibration is essential for maintaining safety and performance standards when you rely on tools like cable tensiometers. These services help verify that your equipment meets industry regulations and manufacturer specifications, giving you peace of mind while you work.

Morehouse offers a comprehensive range of calibration services, including force calibration, torque calibration, and specialized calibrations for aircraft and truck scales.

Each service is designed to meet stringent industry standards, ensuring that your devices perform optimally.

They also provide Tractel calibration and repair services, focusing on maintaining the integrity of your equipment. In addition, Morehouse simplifies the procurement process, making it easy for you to request quotes and understand terms of sale.

Their commitment to customer privacy means you can trust that your data is handled responsibly. You can focus on your projects with reliable calibration services, knowing your measurement devices are accurate and dependable.

Remember, proper calibration isn’t just a recommendation; it’s necessary for achieving consistent, high-quality results in your work.

Company Commitment to Quality

Morehouse Instrument Company prioritizes quality in every aspect of its operations, ensuring that all calibration services and products meet rigorous standards. Their commitment to quality translates into reliable and accurate equipment, which is essential for your calibration needs. They adhere to industry benchmarks and go beyond them, using state-of-the-art technology and methods to enhance measurement accuracy.

Their workforce is highly trained and dedicated to maintaining the highest standards throughout calibration. Every step, from initial setup to final verification, is carefully executed to ensure precision. You’ll appreciate the meticulous attention to detail, which helps prevent measurement errors that could lead to costly mistakes.

Moreover, Morehouse emphasizes continuous improvement in its processes and services.

They stay updated with the latest industry developments to serve you better. This commitment to quality isn’t just about meeting standards; it’s about exceeding your expectations and ensuring complete satisfaction.

When you choose Morehouse, you’re not just getting products—you’re investing in a partnership with a company that genuinely values quality and reliability in every calibration solution it provides.

Frequently Asked Questions

How Often Should Cable Tensiometers Be Calibrated?

You should calibrate cable tensiometers regularly, ideally every six months or after significant usage. Frequent calibration ensures accurate tension measurements, enhancing safety and performance in your applications, especially with varying cable types and conditions.

Can I Calibrate a Tensiometer Myself?

You can calibrate a tensiometer yourself, but it requires specific knowledge, proper equipment, and adherence to manufacturer guidelines. If unsure, consider seeking professional assistance to ensure accurate and reliable calibration results.

What Environmental Factors Affect Calibration Accuracy?

Environmental factors like temperature, humidity, and vibration can impact calibration accuracy. To minimize these influences, ensure you’re conducting measurements in a controlled environment and always follow manufacturer guidelines for optimal results.

Are There Specific Safety Standards for Using Tensiometers?

Yes, there are safety standards for using tensiometers. You should always follow manufacturer guidelines, ensure proper calibration, and wear appropriate personal protective equipment to minimize risks while measuring tension in cables and similar applications.

What Signs Indicate a Need for Recalibration?

You should look for signs like inconsistent readings, drift from known standards, or noticeable wear on the device. If you notice any of these, it’s time to recalibrate your tensiometer for accurate measurements.

Elevate Your Tension Measurements with EML Calibration

Don’t compromise on precision when it comes to your tensiometer calibration needs. At EML Calibration, we understand the critical importance of accurate tension measurements in ensuring both safety and performance in your operations.

Our ISO/IEC 17025:2017 accredited calibration services provide the expertise you need—whether you’re working with GAC or SSAC cables, or require specialized compression calibrations. Our certified technicians use state-of-the-art equipment and follow rigorous protocols to deliver reliable, traceable results.

Contact EML Calibration today at (888) 846-4614 or visit www.emlcalibration.com to schedule your tensiometer calibration. Partner with us to maintain equipment accuracy, extend instrument lifespan, and ensure compliance with industry standards.

Trust the calibration experts—because precision isn’t just about measurements, it’s about confidence in your results.