The future of calibration is bright, driven by automation and advanced technologies that improve accuracy and efficiency. Remote capabilities will allow adjustments from anywhere, cutting downtime considerably. Cloud integration will simplify data management and boost real-time analytics, ensuring precision. Plus, with improved security measures, sensitive data stays safe and secure.

Virtual and expanded reality will revolutionize training and procedures for better understanding and execution. A growing focus on sustainability means adopting practices that reduce environmental impact.

Automation and Remote Capabilities

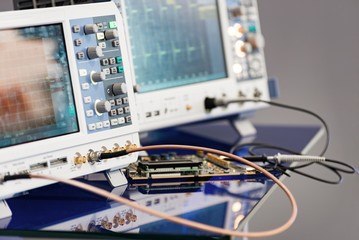

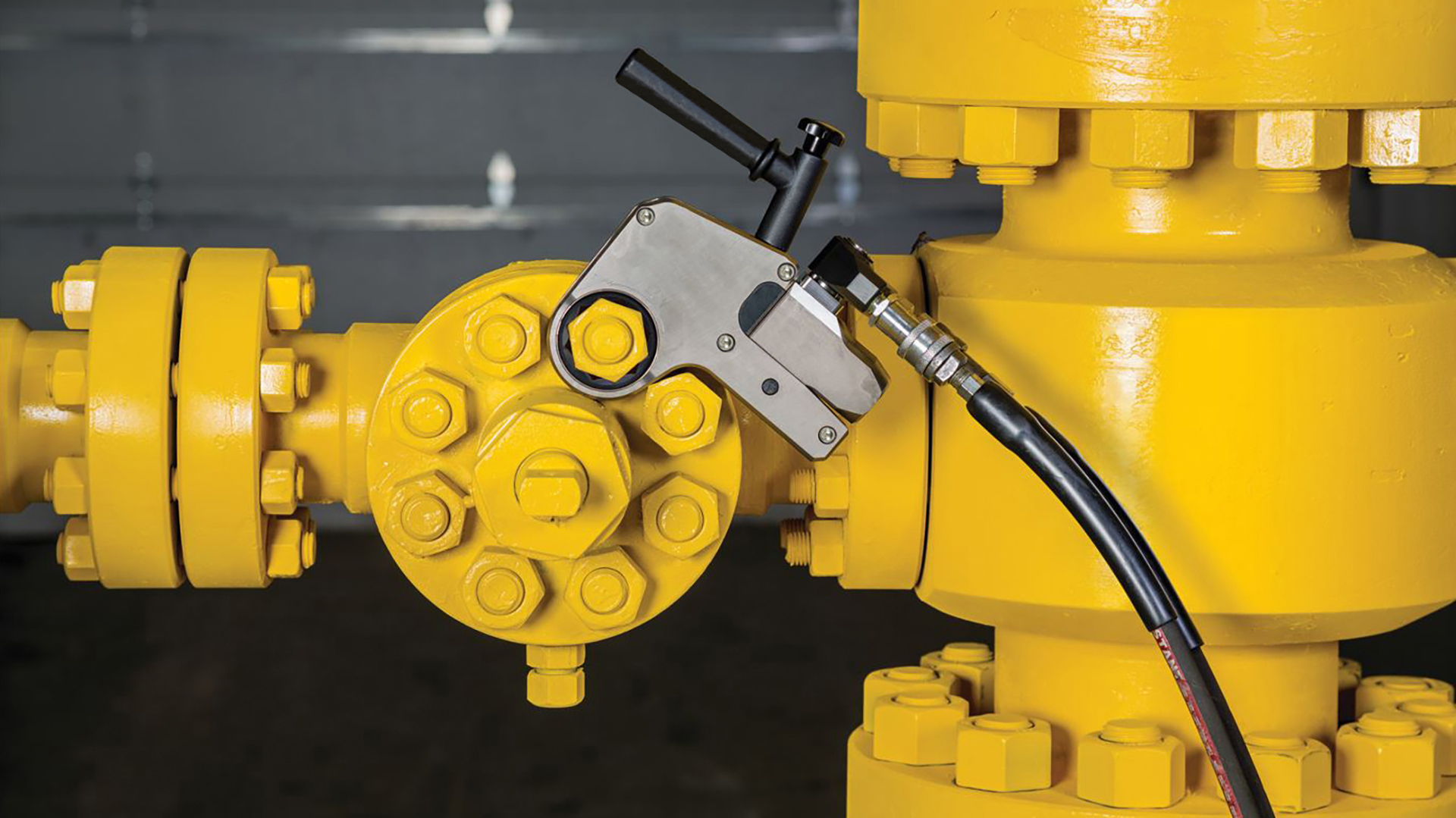

Automation and remote capabilities are set to redefine adjustment services in the near future. Automated systems will improve efficiency, allowing calibration service providers to deliver accurate measurements faster than ever.

Imagine minimizing human intervention while guaranteeing compliance with regulations. With advanced technologies, remote capabilities will enable technicians to fine-tune equipment from virtually anywhere, reducing downtime considerably.

As these innovations progress, predictive maintenance will become a reality, allowing you to anticipate instrument needs before they arise. This proactive approach will boost operational efficiency and will guarantee that your equipment remains in peak condition.

Cloud Integration and Data Management with the Internet of Things

As automation and remote capabilities improve, calibration services, cloud integration, and data management will play pivotal roles in streamlining operations.

Imagine having instant access to calibration certificates, instrument history, and schedules in one centralized hub. This level of organization will improve efficiency and simplify collaboration between you and your calibration provider.

With real-time data analysis, you’ll gain insights that help guarantee accurate readings and maintain instrument precision. Predictive maintenance will become a reality, allowing you to anticipate issues before they arise, reducing downtime and unnecessary recalibrations.

Cloud integration means that calibration data is accessible from anywhere, making it easier to manage your instruments. This automation lets you focus on what truly matters—guaranteeing your equipment performs at its best.

The Internet of Things (IoT) enables continuous monitoring, ensuring your devices operate at peak performance. This real-time capability helps maintain accuracy while simplifying data management. Imagine having all calibration records and schedules in a centralized cloud hub, making collaboration seamless and efficient.

Enhanced Security Measures

Adopting advanced technologies in calibration boosts efficiency and accuracy but also raises security stakes. Integrating automation and remote calibration capabilities requires you to implement advanced security measures to protect sensitive calibration data.

Encryption will safeguard information during transmission and storage, ensuring data integrity against potential breaches.

With the rise of the Internet of Things (IoT), devices will become increasingly interconnected. This connectivity could also come with more risks. Stringent access controls and compliance with industry regulations must be implemented to reduce any risk. The data you collect and analyze requires heightened protection. A security breach could compromise your operations, client trust, and business continuity.

By prioritizing advanced security measures, you protect your assets and reinforce your commitment to responsible calibration practices.

Virtual and Augmented Reality

Virtual Reality (VR) and Augmented Reality (AR) can improve technician training and calibration procedures. A technician could practice complex tasks in a risk-free VR environment, gaining confidence before handling actual equipment. AR overlays could provide step-by-step guidance during calibrations, enhancing accuracy and reducing errors.

With VR, technicians could engage in realistic scenarios, practicing intricate calibration procedures without risking damage to expensive equipment. These engaging environments will improve skills and help develop confidence and proficiency in a safe setting.

AR may take this further by overlaying real-time information onto physical instruments, guiding a technician through complex calibrations. They’ll receive instant feedback, helping them understand the nuances of each task while ensuring accuracy and efficiency.

Embracing VR and AR in calibration could lead to a new era of expertise, safety, and accuracy.

Sustainability Focus

As the calibration industry adopts cutting-edge technologies like VR and AR for training and efficiency, it must prioritize sustainability.

By implementing optimized calibration schedules, your company can enhance accurate measurements and reduce energy consumption.

Digital documentation reduces paper waste and allows you to track calibration histories efficiently. Furthermore, using cloud-based systems can aid in minimizing waste by ensuring that you’re only recalibrating, when necessary, further promoting sustainability.

Opting for energy-efficient instruments and practices will help reduce overall energy consumption.

As the calibration landscape evolves, integrating sustainability into your operations isn’t just beneficial—it’s vital. By focusing on these strategies, you’re future-proofing your business and contributing to a healthier planet.

The future of calibration can be both technologically advanced and environmentally responsible, ensuring that you meet industry demands without compromising the earth’s resources.

A Glimpse into the Future of Calibration

Imagine stepping into a future where the calibration of your instruments is seamlessly integrated with the digital world. Remote capabilities and cloud connectivity grant you instant access to your calibration data, regardless of location.

Cutting-edge technologies ensure the flawless operation of your instruments while robust security measures safeguard your valuable information. Furthermore, this future embraces sustainability, allowing you to contribute to a greener planet.

This is the future of calibration – a future marked by automation, connectivity, and an unwavering commitment precision.

The future looks bright for electronic and mechanical calibration. For the best-in-class calibration, both on and off-site, contact EML Calibration today.